order before 2pm

Mise à l'échelle des processus FMCG pour répondre aux besoins de votre petite entreprise

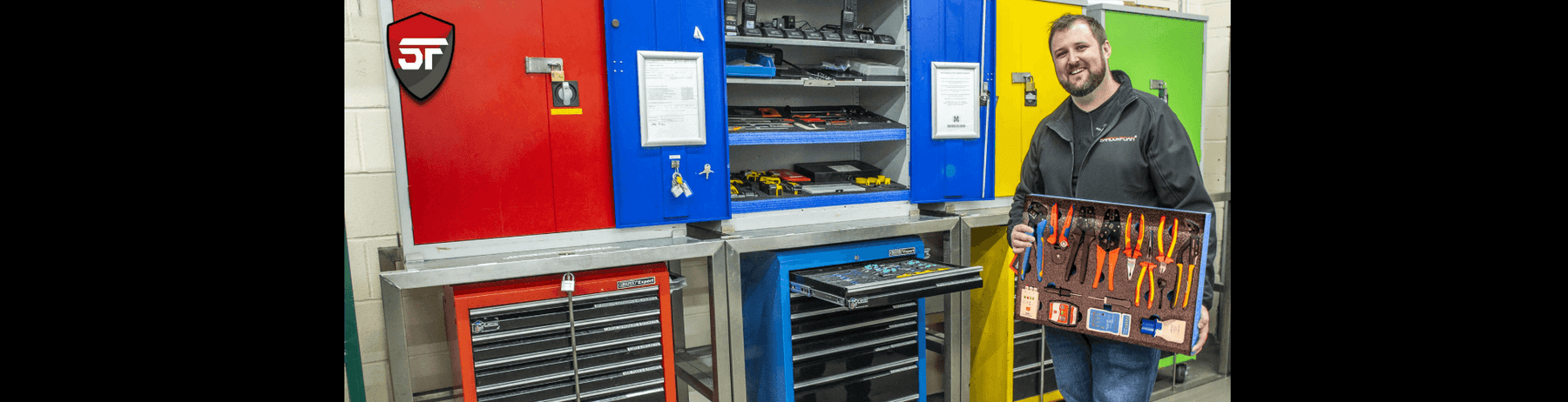

Nous avons récemment envisagé le augmentation de l'utilisation du contrôle des outils DIY produits pour atteindre et dépasser les exigences de contrôle des outils parmi certains des plus grands acteurs dans le secteur des FMCG avec lesquels nous travaillons. Alors, comment ces principes peuvent-ils être étendus pour être appliqués ailleurs ? Est-il possible que des petites entreprises dans d'autres domaines en dehors de ce secteur puissent tirer des leçons des processus FMCG pour les appliquer à leurs propres entreprises ?

Nous le pensons certainement, et voici ce que nous considérons comme les points clés qui peuvent vraiment bénéficier à quiconque, dans n'importe quel domaine de la vie :

Entretien régulier et programmé:

Si vous utilisez un quelconque équipement, machine, outils ou technologie dans votre entreprise, et soyons honnêtes, de nos jours, qui ne le fait pas, alors ceci est pour vous.

Leçon FMCG: L'entretien régulier des outils et équipements est une pratique standard pour prévenir les pannes inattendues et garantir une qualité constante.

L'appliquer à d'autres entreprises: Établissez des routines et prenez le temps d'entretenir et d'auditer tous les outils et équipements essentiels à votre entreprise. Cette approche proactive prolongera la durée de vie de vos actifs, vous permettant d'économiser à long terme. Comme l'utilisation d'un produit tel que Shadow Foam pour protéger votre équipement précieux. De plus, cela devrait prévenir des temps d'arrêt coûteux en cas de pannes ou de services et réparations essentiels.

Standardisation des procédures:

Nous devons tous travailler à la volée, ou de manière ad hoc parfois. Flex et l'adaptabilité sont importants. Mais la standardisation de nombreux processus peut être vraiment bénéfique.

Leçon FMCG: Les procédures opérationnelles standard (POS) garantissent la cohérence et l'efficacité dans l'utilisation et l'entretien des outils.

L'appliquer à d'autres entreprises: Appliquez vos propres SOP pour l'utilisation, l'entretien et le stockage des outils. Former le personnel sur ces procédures peut améliorer l'efficacité et réduire les erreurs. C'est là qu'un produit comme Shadow Foam peut vraiment prendre toute son importance.

Investir dans des outils de qualité:

Remarque, nous disons 'qualité', pas 'cher'. Si notre trousse à outils à prix réduit les projets nous ont appris que le bon n'a pas toujours à être coûteux.

Leçon FMCG: Les outils de haute qualité sont moins susceptibles de tomber en panne et peuvent résister à une utilisation rigoureuse, ce qui est essentiel pour maintenir la qualité de production.

L'appliquer à d'autres entreprises: Dans certains cas, l'adage « acheter bon marché, acheter deux fois » peut s'appliquer. Mais ce n'est pas toujours vrai. Investir dans des outils de haute qualité peut entraîner des économies à long terme grâce à une réduction des temps d'arrêt et à moins de remplacements sur une plus longue période, alors faites des recherches et achetez intelligemment. Et considérez Shadow Foam comme le moyen idéal pour protéger la durée de vie de ces investissements également.

Suivre l'utilisation des outils et l'inventaire:

Plus facile à dire qu'à faire quand il y a de nombreuses mains ou plusieurs zones de travail en jeu. Cependant, c'est la clé, et produits d'organisation comme Shadow Foam vous aidera vraiment avec cela.

Leçon FMCG: Des méthodes de suivi efficaces sont utilisées pour surveiller l'utilisation des outils et l'inventaire, aidant à prévenir les pertes et à garantir la disponibilité.

L'appliquer à d'autres entreprises: Mettre en œuvre un système de contrôle des outils pour suivre l'inventaire et l'utilisation des outils. Cela aide à planifier les achats et à s'assurer que les outils sont disponibles lorsque nécessaire. Avec Shadow Foam dans le cadre de cette stratégie, vous ne perdrez plus jamais un outil.

Adoptez les principes "Lean":

tant que petite entreprise nous-mêmes, nous chez Shadow Foam aimons appliquez nos valeurs lean dans notre façon de travailler aussi, donc ces grandes méthodes commerciales sont vraiment évolutives ailleurs.

Leçon FMCG: Les principes du lean manufacturing, tels que la minimisation des déchets et l'optimisation des processus, ne s'appliquent pas seulement à des éléments comme le contrôle des outils, mais aussi à de nombreux autres domaines de l'organisation.

L'appliquer à d'autres entreprises: Commencez facilement en appliquant les principes du lean à votre propre gestion des outils – l'utilisation de Shadow Foam signifiera que vous pouvez trouver le bon outil du premier coup à chaque fois, vous faisant gagner des heures à long terme sans chercher des objets perdus ou mal placés.

Concentrez-vous sur l'amélioration continue:

Encourager une culture d'amélioration continue parmi les employés en utilisant des méthodes comme Shadow Foam organisateurs d'outils peut créer un espace de travail plus cohérent, harmonieux et dynamique entre collègues.

Leçon FMCG: Les processus d'amélioration continue aident à évaluer et à améliorer régulièrement les mesures de contrôle des outils.

L'appliquer à d'autres entreprises: Révisez et améliorez régulièrement vos propres pratiques de contrôle des outils en fonction des besoins de votre équipe, des demandes des clients et des expériences en cours.

résumé...

adoptant ne serait-ce que certaines de ces pratiques, les petites entreprises de nombreux secteurs peuvent constater une grande différence. Améliorez l'efficacité opérationnelle, réduisez les coûts, améliorez la qualité des produits et assurez un environnement de travail plus sûr, tout comme n'importe quel grand concurrent dans le secteur des FMCG.

Évidemment, Shadow Foam et l'utilisation d'approches lean et contrôlées pour votre organisation et stockage ne sont qu'une petite étape dans ce voyage, mais c'est une étape importante, peu coûteuse et facile à appliquer. Alors essayez Shadow Foam aujourd'hui comme un gain rapide et facile dans votre démarche pour reproduire les processus des grandes industries au sein de votre propre petite entreprise.