Daily order cutoff at 2pm

Hvor gode er Dewalt ToughSystem 2.0-skufferne?

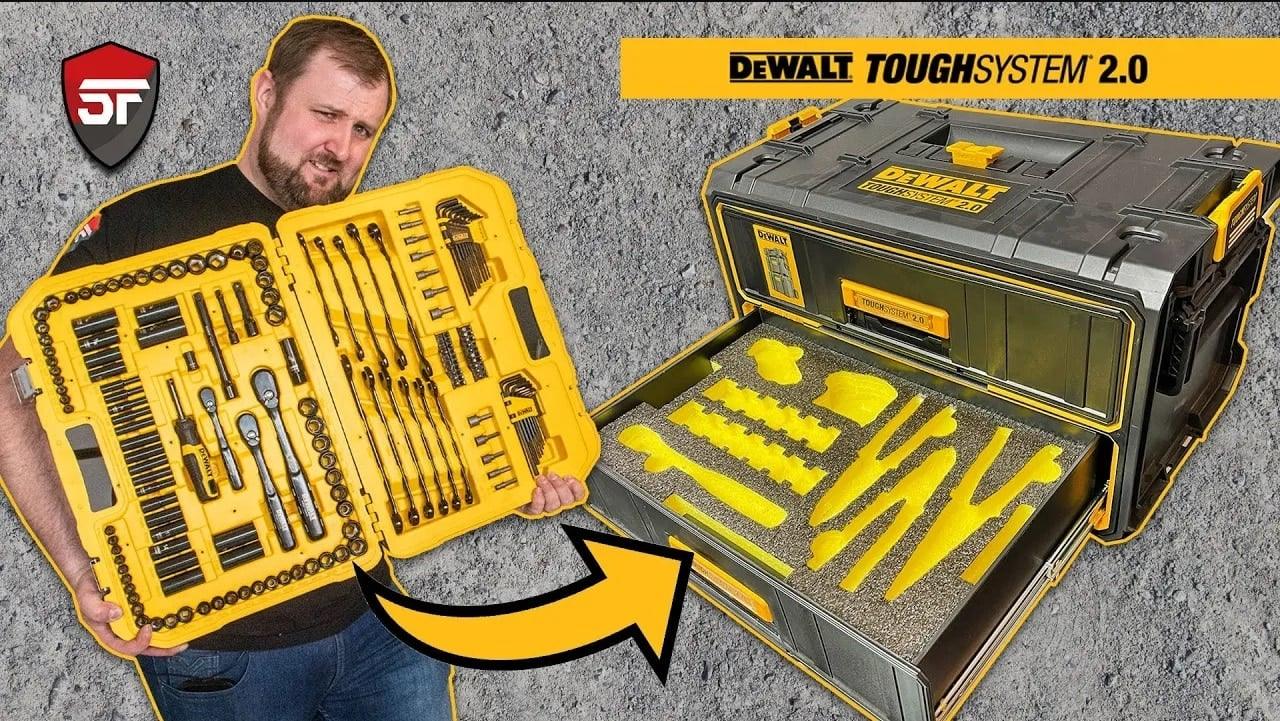

We are on a mission to create the most organised DeWalt Toughsystem 2.0 toolbox stack in the world! With a helping handful of Shadow Foam, this week, we are tackling the drawer box and dialing it in to house over 200 DeWalt hand tools! Can we do it?

We’ve already done projects like turning the Tough System 2.0 into a battery charging case. As well as organising a whole Dewalt ToughSystem 2.0 stack. But today it’s the turn of the drawers. So, just how good really are Dewalt ToughSystem 2.0 Drawers?

What’s going in the drawers?

Ours previously housed some power tools, but now feel we can get much better use of them storing hand tools. We already had some Dewalt hand tools, but supplemented these with what looked to be a beast of a set of Dewalt £108 socket set with drivers etc from Costco. On the face of it, it really looked like we were getting a lot for our money. The socket wrench looked OK and so did the spanners. They’re powder coated, so look really good. But you’d really need to see how the coat looked after a bit of use. One of the main criticisms though is that while they are marked according to size, they’re really hard to see the sizes.

Weirdly too there’s a single spark plug socket. Strange for a set that seems to be more pulled together for a building site. There are allen keys too – both metric and imperial but not ball-end. The bit set seems a bit cheap – it’s a full bit set, but they keep dropping out. Also there’s no 10mm spanner which is the most commonly used size in the UK. So things like that seem a little odd. In our opinion it’s reasonable value for money. But we think the comparable Halfords set with a lifetime warranty seems better quality.

Overall we’ve earmarked 200 tools between both sets that we want to use to house the tools in the two drawer unit.

How it’s organised

The Dewalt ToughSystem 2.0 drawers are fantastic and deep. So the plan is, with so many tools to house, we are going to use a 30mm base layer containing tools with a removable 50mm insert on the top in each drawer. So for the whole project we needed 1 x 30mm twinpack of inserts and 1 x 50mm twin pack.

One of the longest parts of the process is organising the tools to get maximum efficiency. Here, the drivers have been sorted into sizes for quick and easy reference. We take a picture once we’re happy with our layout before we even start cutting.

Hacks

SOCKET SETS

We are always being asked how you can cut socket sets into foam without spending hours doing each and every socket separately. We do like it that way, but appreciate it can take a whole. So when we’ve tried to do it with a quicker method in the past, we’ve tend to use a rail; so sit the sockets on the rail then cut the rail into the foam. But what if you don’t have, or don’t want to be buying a rail? Here we used a different technique to help make life easier for you. Essentially lining them up while they’re laying down, and cutting them in all together.

REMOVABLE TRAYS

We’ve added foam layers as removable trays in the past, but one upgrade we’ve made here is by adding cut-outs to the side of the inserts to help them be removed nice and easily when you need tools from the layers beneath. Check out our Dewalt toolbox organisers here.

Take a look and see what you think!