Chiusura giornaliera degli ordini alle 14:00

Come fare un banco da lavoro con un budget limitato

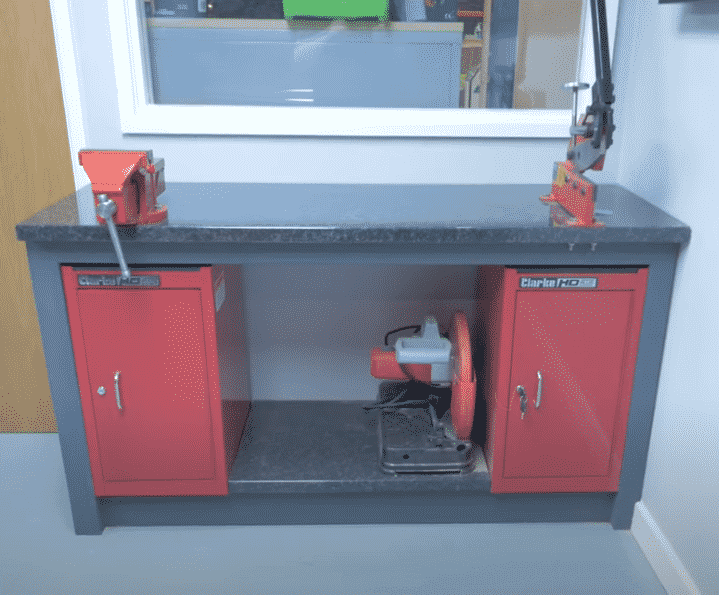

Avevamo bisogno di creare un banco di lavoro per liberare lo spazio disordinato del nostro studio e sfruttarlo meglio. Abbiamo alcuni progetti entusiasmanti in arrivo e abbiamo davvero bisogno dello spazio aggiuntivo che creerebbe un banco di lavoro. Ma volevamo anche farlo con un budget limitato. Quindi abbiamo riproposto due armadietti per utensili Clarke HD e alcuni residui della superficie di lavoro per creare un'area di lavoro salvaspazio e multiuso e un posto dove vivere la nostra piccola sega a nastro Axminster, troncatrice per metalli e troncatrice.

Dai un'occhiata e guarda la build completa qui !

Avevamo già un piano di lavoro di 40 mm avanzato da quando abbiamo alloggiato le nostre cabine. Non abbastanza per tutto ma sicuramente sufficiente per uno scaffale. Ma dovremmo comprarne altri per la parte superiore. Avevamo anche i nostri armadietti per attrezzi Clarke HD che originariamente dovevano essere armadietti laterali per la nostra cabina a rulli. Ma non è andata proprio così perché erano molto più brevi. Quindi questo è davvero un ottimo modo per riproporli.

Abbiamo calcolato che avremmo avuto bisogno di circa 20 metri di legname 3×2 CLS insieme all'officina aggiuntiva per recarci al nostro B&Q locale per ottenere ciò di cui avevamo bisogno.

Progettare il gabinetto.

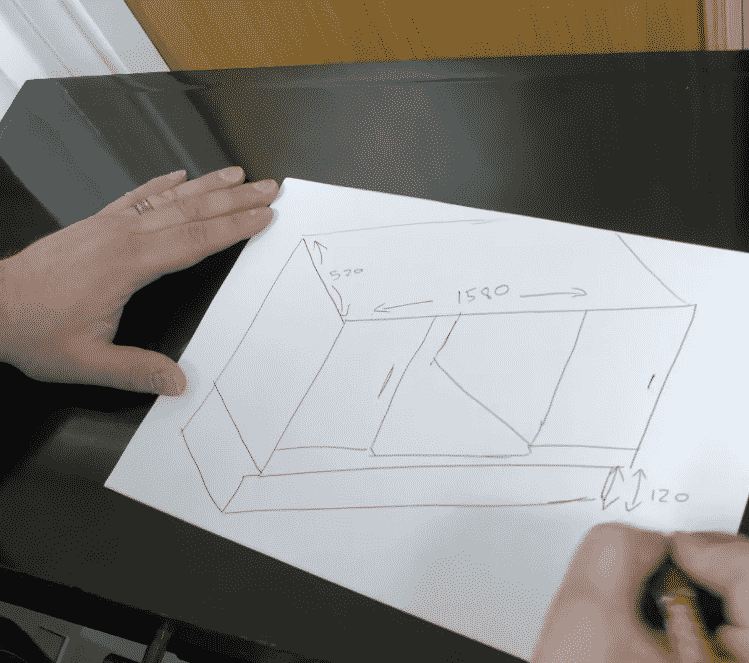

Come diciamo sempre, la pianificazione è la parte più importante del processo. Quindi Jonathan, come sempre, ha redatto i suoi piani per la costruzione per fornirci lo spazio di archiviazione ottimale e salvaspazio che desideravamo per lo scopo.

Conoscevamo l'altezza ottimale che volevamo per il servizio di lavoro principale e, ovviamente, l'altezza degli armadi Clarke Tools riconvertiti, quindi il resto è stato pianificato attorno a quella.

Tuttavia, a quanto pare, ciò che non abbiamo considerato correttamente in questi piani è stato:

* Larghezza della base

Abbiamo reso la base un po' troppo larga per adattarsi allo spazio.

* Altezza ripiano

La sega a nastro che ha ispirato il banco da lavoro non poteva essere posizionata sotto il bancone. Ad una certa distanza! Ops.

Ma come si suol dire “non commettiamo errori, facciamo felici incidenti!” Ogni giorno è un giorno di scuola...

Adattare la costruzione

È stato facile superare la larghezza del mobile poiché abbiamo semplicemente rimosso una piccola sezione del battiscopa e abbiamo ottenuto la soluzione perfetta.

Tuttavia, dato il problema riscontrato con la struttura e l'altezza dello scaffale, abbiamo dovuto adattare leggermente il suo utilizzo. Abbiamo aggiunto a un'estremità del piano di lavoro una morsa per carichi pesanti e all'altra estremità una cesoia per il taglio dei metalli Sealey. Quest'ultimo è qualcosa che ci sarà davvero utile in quanto può tagliare l'acciaio fino a 6 mm e sarà prezioso in un progetto che avremo presto.

Quindi la sega a nastro Axminster sta ancora cercando una casa. Ma è bello essere flessibili a volte con queste cose, giusto!?

Il risultato

Quindi, per meno di £ 150 e in circa 4 ore, siamo riusciti a realizzare un banco da lavoro finito. Non ha soddisfatto del tutto il nostro brief originale, ma ne siamo comunque abbastanza soddisfatti. Sarebbe bello sapere cosa ne pensi e se c'è qualcosa che avresti fatto diversamente.

Eravamo anche entusiasti del fatto che questo progetto “bootstrap”, come lo chiamavamo, fosse stato ripreso dalla nostra stampa locale, con il Northwich Guardian che pubblicava questo pezzo su di esso.

Ci piacerebbe anche vedere se hai provato a realizzare un banco da lavoro. Il nostro obiettivo è ispirare idee e condividere ciò che gli altri creano per ispirare gli altri. Quindi controlla i nostri social per ulteriori idee o per condividere le tue creazioni epiche. La nostra community di Facebook è il luogo ideale per ottenere supporto e consigli anche sulle marche, quindi chiama!

Kit di taglio gratuito per ordini qualificati

Kit di taglio gratuito per ordini qualificati

Oltre 3.000 recensioni positive

Oltre 3.000 recensioni positive

Oltre 500 video su YouTube

Oltre 500 video su YouTube

Assistenza nel Regno Unito

Assistenza nel Regno Unito